Motor manufacturers are on a never ending quest to try and reduce weight and try and improve fuel efficiency, this is even more apparent this week where crude oil reached a sterling all-time high, Ford have announced that they have taken inspiration from the Aero chocolate bar to produce lighter plastic parts by injecting gas bubbles during the manufacturing process.

Motor manufacturers are on a never ending quest to try and reduce weight and try and improve fuel efficiency, this is even more apparent this week where crude oil reached a sterling all-time high, Ford have announced that they have taken inspiration from the Aero chocolate bar to produce lighter plastic parts by injecting gas bubbles during the manufacturing process.

Notoriously plastics are a difficult to save weight on without compromising strength, durability, or function. But Ford has found a new technique to shed the pounds.

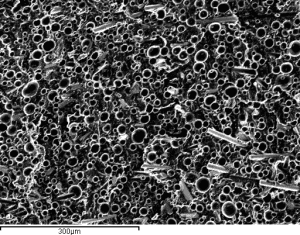

MuCell technology introduces gas bubbles into the plastic as it is moulded, leaving a microscopic honeycomb structure. These tiny spaces save weight by reducing the amount of plastic used, without compromising the integrity of the part.

Weight plays a key role in vehicle emissions and reducing the overall mass of the vehicle results in improvements to fuel economy and carbon emissions.

MuCell technology expert Carsten Starke is excited by the potential of the new process. He says: "The first time I saw this plastic under the microscope I thought to myself it looks like an Aero chocolate bar! The bubbles in the chocolate change the taste, but in our plastics they save weight and making cars lighter reduces emissions and fuel consumption significantly.

The MuCell technology will see its first application in engine covers which will be rolled out over the next few years on vehicles such as Focus, C-MAX and Grand C-MAX, S-MAX, Mondeo and Galaxy. Ford has committed to a minimum of 100kg weight reduction from even its smallest cars and 300kg from larger cars by 2020 as part of its environmental initiatives.

A range of other measures including automatic stop-start engines, aerodynamic grille shutters and low rolling resistance tyres make Ford’s ECOnetic models amongst the most efficient on sale.